The Power of Process Routing

Some things are worth more than the sum of their parts! Not least in manufacturing, where the material costs of components are just the start of the true cost price of your shiny new finished goods. Extensive work, assembly, processing and labour goes into making something special – and this is where many businesses add their most value to the bottom line.

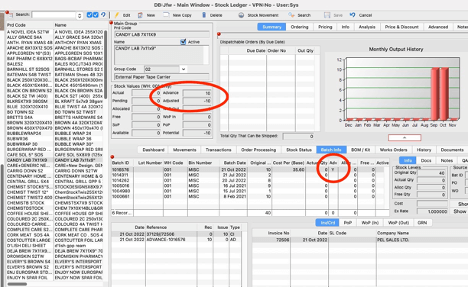

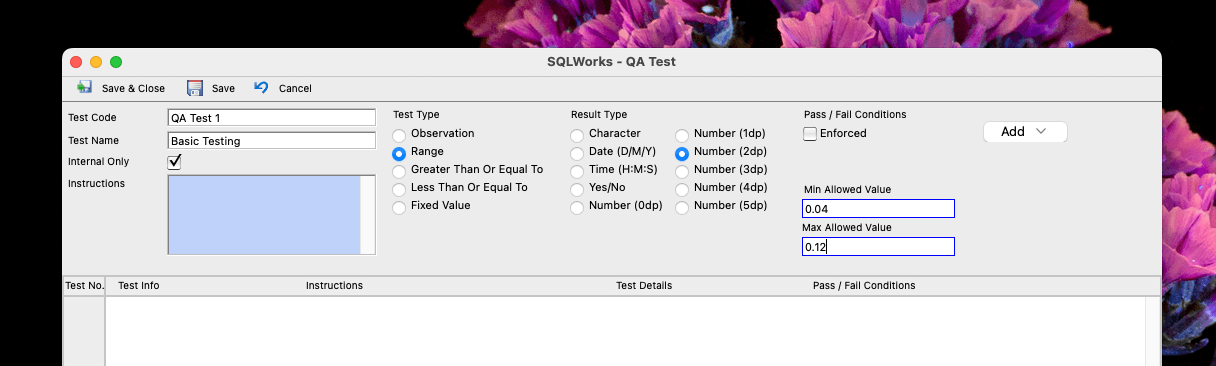

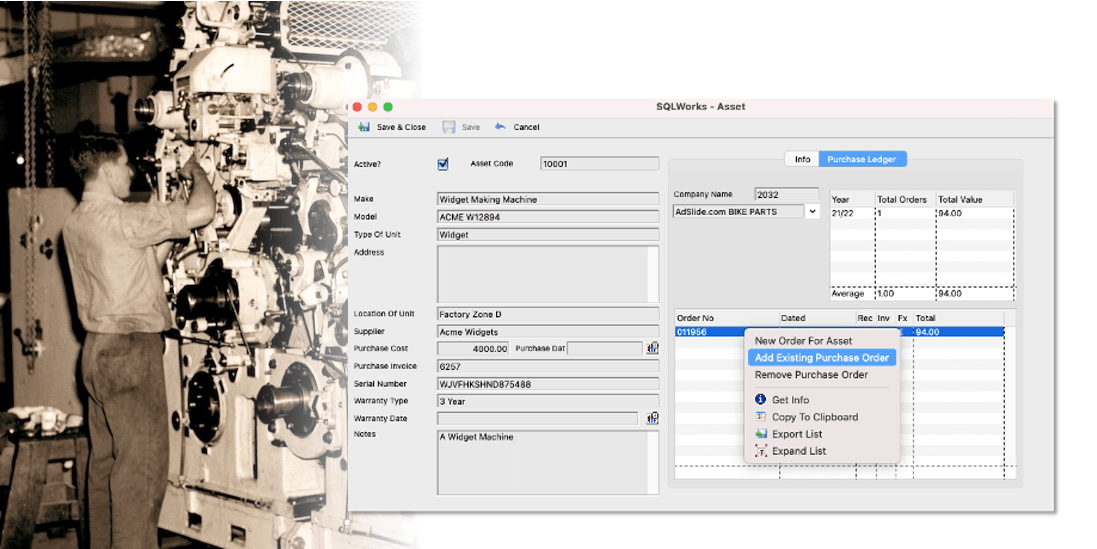

Process Routing is a special SQLWorks tool to help Production Managers organise, track and cost this essential part of the business workflow – ensuring finished goods are not only ‘made’ efficiently, but also priced appropriately.

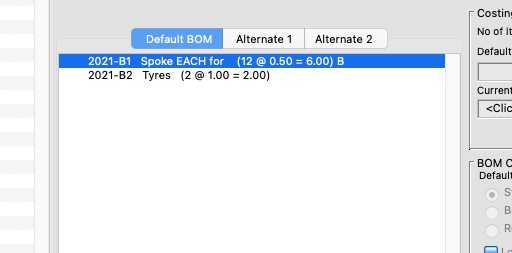

If you have the Manufacturing module enabled, default Process Routes in SQLWorks can be assigned to the Bills of Material of any stock item, and these become the default process route for all new Works Orders instructing your team to make that item.

How Process Routing Works

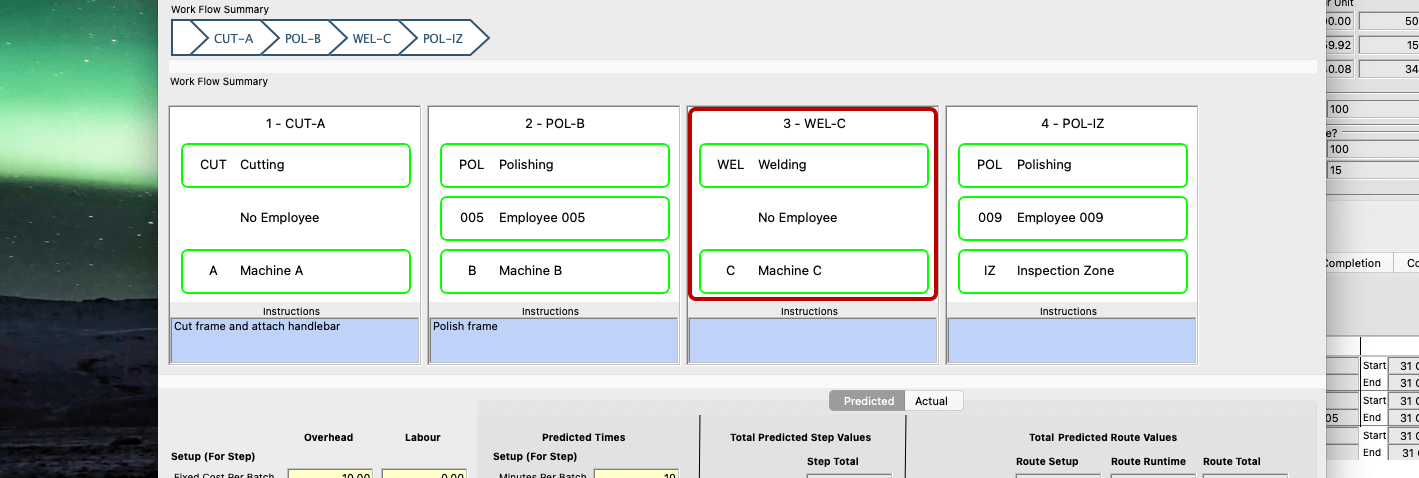

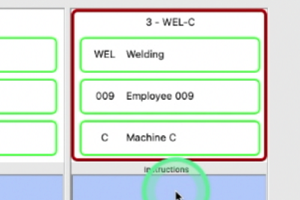

Each Route is comprised of a series of process steps, each of which is given up to three attributes:

- Process Type – a ‘type’ of work, from a list defined by your business (mandatory.)

- Work Centre – a location where work happens, such as a piece of machinery or factory zone.

- Employee – a specific person, authorised to carry out that step in the process route.

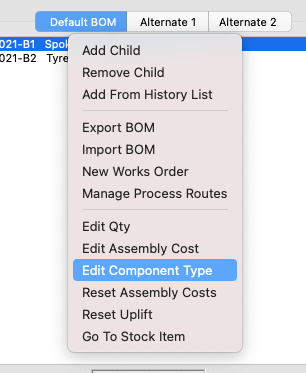

To build a process route, simply drag and drop processes, work centres and employees onto a BOM’s process route, building up the chain of default steps needed to make the finished item. The route is automatically added to each new Works Order for that BOM.

(However, if an individual Works Order needs a different route on a specific Works Order, you can either ‘Change’ to a different pre-saved route with different steps, or ‘Edit’ the steps given to that specific Works Order using the default as your starting point, but adding your variations. Future Works Orders for this item will still use the BOM’s default process route, unless it is also updated.)

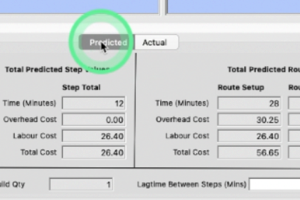

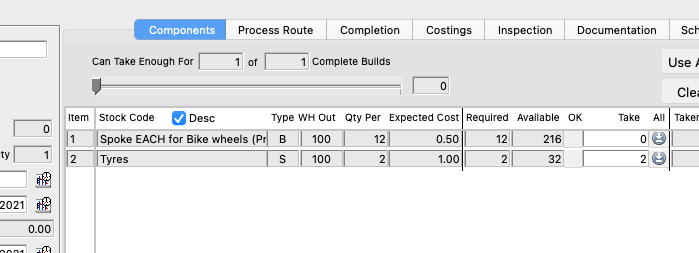

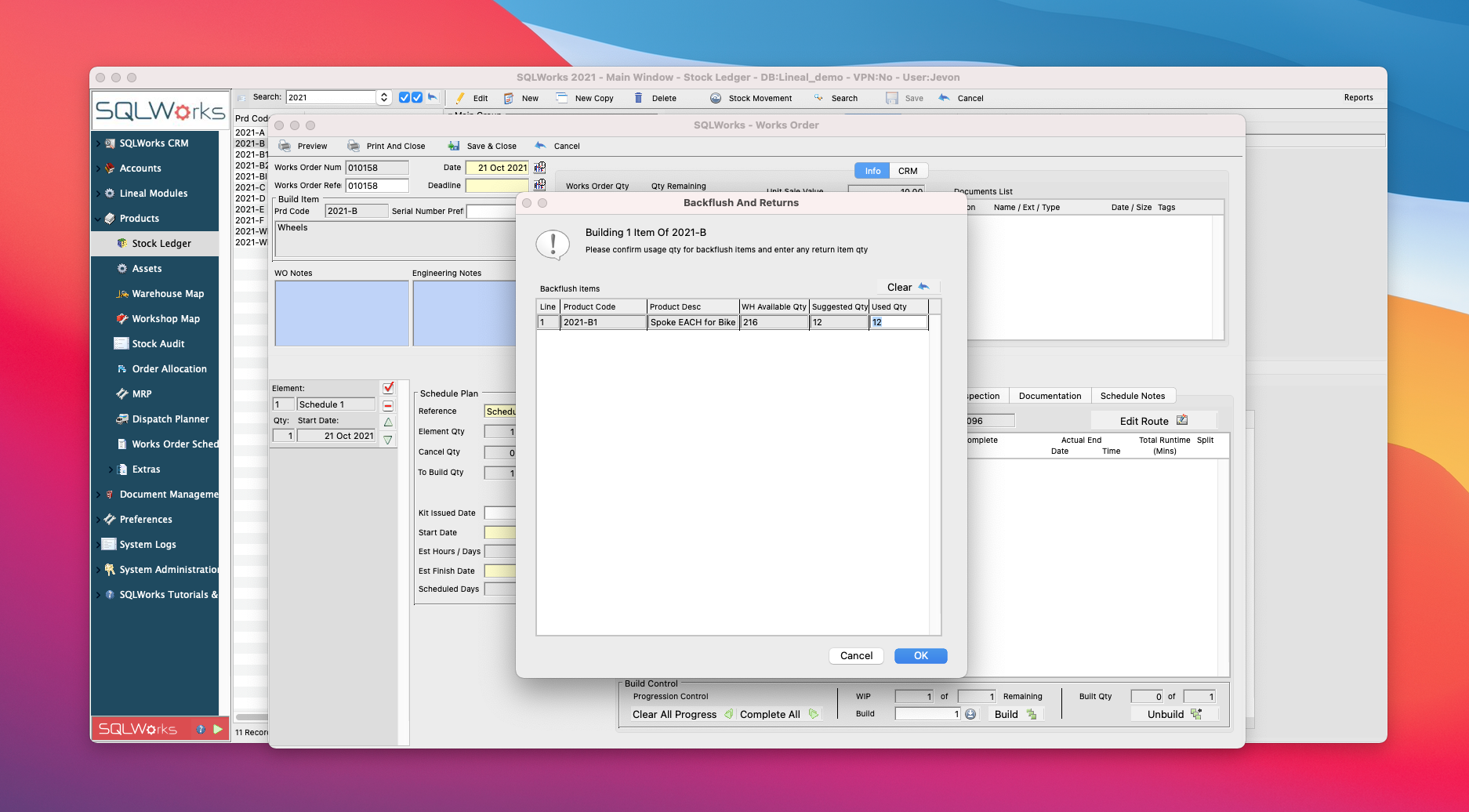

Each and every step on a Process Route can optionally contain detailed costings – based on labour and setup fees/time expired. In addition to setting your ‘Expected’ costs, you can use progress tracking to generate an ‘Actual’ cost for every step, and compare the two for an accurate picture of profitability.

Your factory may be full of active Works Orders, all taking different Process Routes on their journey to completion.

Key Benefits

There are several key benefits here:

-

Organised Production

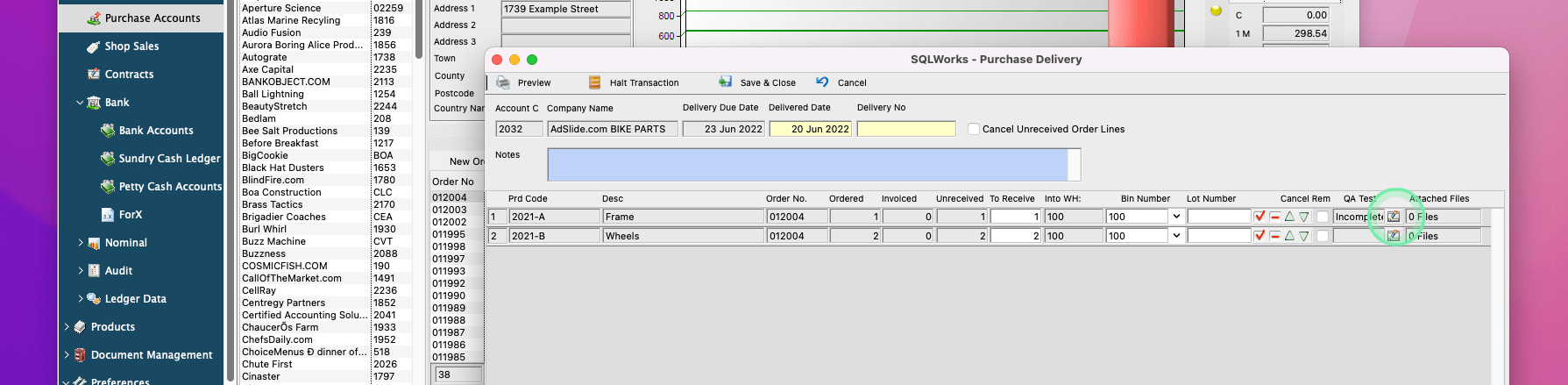

Use a single pane of glass to define (or re-define) your shopfloor’s master-plan centrally. Redirect works orders and the instructions that appear on them when you need to respond to events, control how and where work should be done, assigning it to the right people for maximum efficiency.

-

Identify Bottlenecks

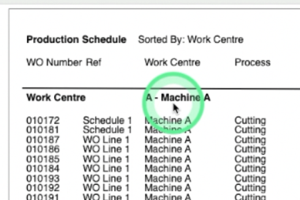

With a structured view of types of work, the places where they happen, and the personnel assigned to do them, production reporting allows production managers to instantly shuffle the outstanding schedule of works orders to get an accurate sense of workloads – from any perspective.

-

True Profitability

The real holy-grail of manufacturing: compare your expected vs actual production costs, factoring in setup and runtime, labour and overheads, for every item of finished goods – to establish exactly how profitable it was to make, and what the true sale price should be.

Optional Extras

Depending on how you use Production Routing we’ve included extra controls to better fit the different kinds of business operations – and help you make better decisions. You can choose how to use all of these to get the most value from our software – or speak with our software development team, to introduce something entirely new.

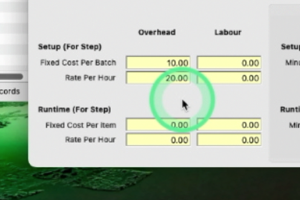

Setup vs Runtime

The journey of a thousand miles begins with one step – but is this production run worth the effort? Factor in both the setup and runtime cost of each production step for an accurate costing of each stage of the process route, whether you’re making a single widget, or a thousand.

Labour vs Overhead

Personpower and overheads are not the same thing, so why cost them as such? Split your production costs for each step into overhead and labour, and know exactly where your profitability (or unprofitability) for any part of the production route derives from.

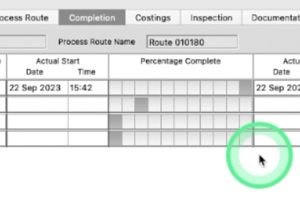

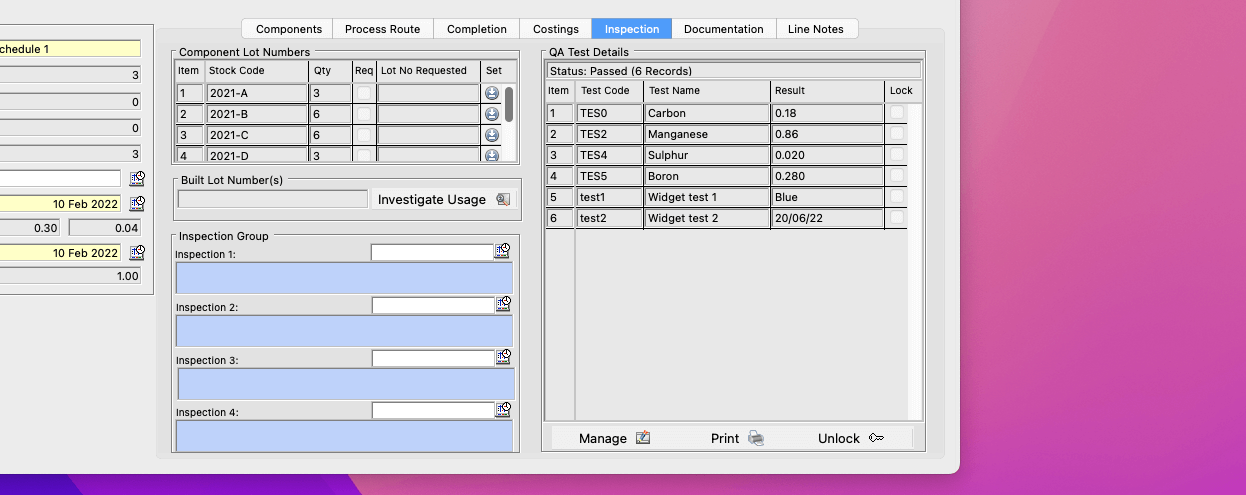

Completion %

You’ll finish it on Monday, right? Update any step on the process route with a completion percentage if you need more granular production tracking. Don’t worry about the maths – based on your predicted production costs, SQLWorks will automatically calculate how much cost has been incurred so far.

Role Restriction

Lock certain types of work to the employee with the training, skills and proficiency to do it, by setting defaults on your process routes for those steps. Need to make sure one of the old hands does the tricky bit? Make it part of the standard operating procedure.

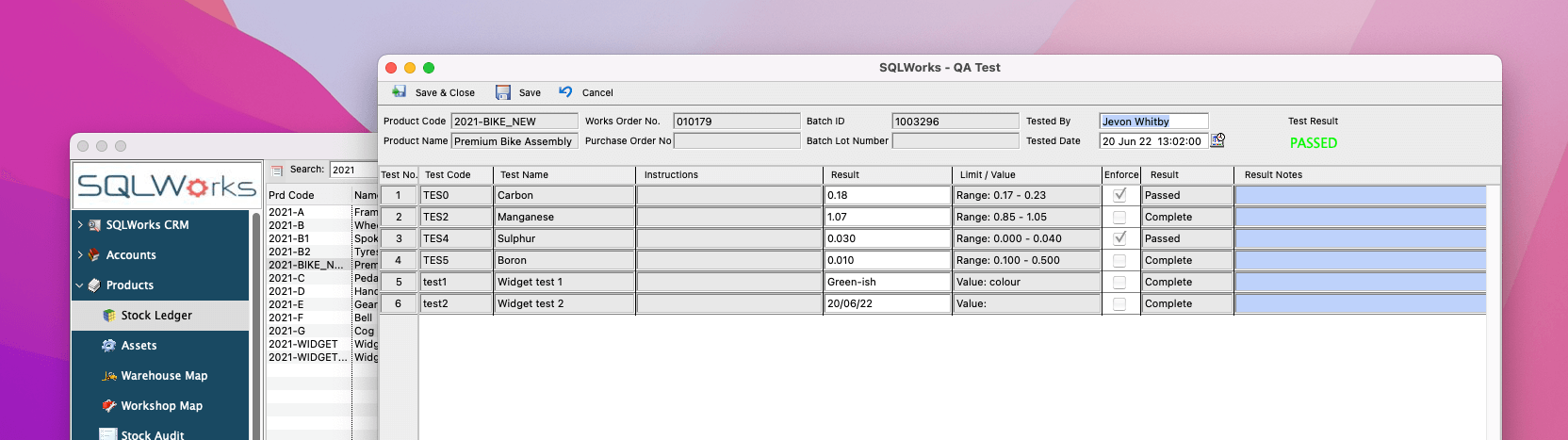

Actual vs Expected

The Holy Grail of manufacturing – compare your predicted against actual costs incurred for any step on the process route, generating a forensically-accurate production cost for every stage, of every item of your finished goods. Get a detailed picture of profitability… and know exactly what to quote next time.

Production Reporting

Balance the load across your entire factory and identify bottlenecks at any machine, process type or employee. Production Reporting allows you to see exactly where the biggest burden of outstanding Works Orders will route via, and allow you to plan accordingly.

Thanks for reading! For Production Routing and manufacturing software expertise, please contact our team today.