How MRP Revolutionises Purchasing

Good news! You’re in charge of a manufacturing business. Design an amazing finished product, buy its component parts, and set your team to work. Make something incredible and the World will surely beat a path to your door. Like so many industrialists before you, you are destined for greatness. As your finished goods are assembled you can watch your genius turn into innovation, skill into added value, and fame into fortune.

Well… maybe. But as your business scales, it becomes harder and harder to keep track of all the materials you need (and when you need them) to keep manufacturing on schedule. Disruptions begin to bite and there’s costly overheads everywhere you look, even underfoot.

Enter the MRP Run – a powerful process that some of the World’s most efficient manufacturing companies use to control purchasing and production. Using intelligent MRP software, even small businesses can organise sophisticated manufacturing operations without mistakes.

How MRP Works

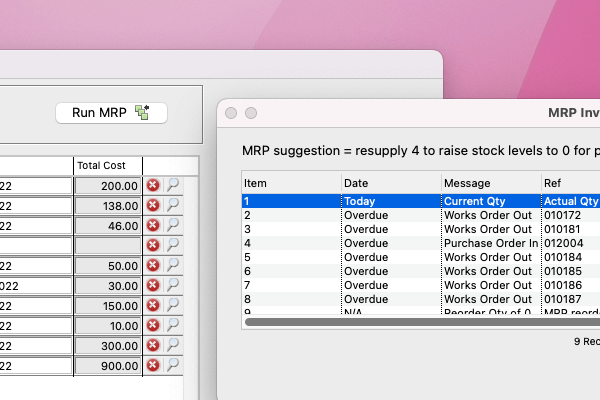

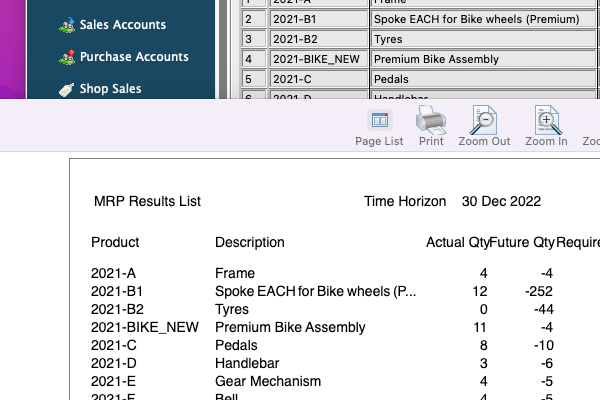

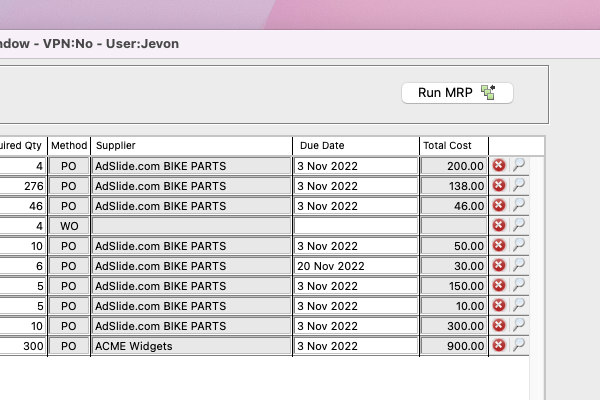

Each time you begin an MRP run, SQLWorks scans through all your Sales (and Works) Orders, looking for demand for stock. It calculates which stock is already available, checks if components and materials are needed, and brings back recommendations. Those recommendations may be draft Purchase Orders (‘we need to buy A from Supplier B’) or Works Orders (We need to make X with Y.’)

For you, the human in the driving seat, things have changed. Your job is no longer the drudgery of compiling dozens of order lines, but to review MRP’s findings carefully, sense-check them, and be the authority that approves the next steps.

But think big! Unlike a human, MRP can scan through hundreds of orders, through multiple levels of Bill of Materials, cross-checking against tens of thousands of stock lines, bring back exact results in moments, and even prepare the paperwork for you to approve outgoing emails.

That automation potentially saves hundreds, even thousands, of person-hours creating routine purchase orders and works orders manually – and revolutionise the logistics behind manufacturing.

Key Benefits

There are several key benefits here:

-

Optimised Buying

The bigger your business, the harder it becomes for one person to ‘see’ the whole picture themselves. Integrated MRP software has a much clearer visibility of both the stock you hold and the demand that’s coming, and can make clear decisions about quantities needed than even the World’s most perceptive purchasing manager.

-

Better Timing

As long as your Sales and Production teams are logging demand for stock via Sales Orders and Works Orders, MRP can ‘look ahead’ into the future; warning you of stock shortages before they happen and making sure they are avoided. Delays cost money, so become a scheduling champion.

-

A Stress-Free Life

Well not entirely, but it’s true that MRP can save many hours of staff time doing routine admin. Like other automation, MRP is particularly good at the ‘mundane’ work: volume purchasing that involves lots of lines and SKU codes. While these are not difficult for a human, it’s often not the best use of their time.

Optional Extras

Depending on how you use MRP we’ve included extra controls to better fit the different kinds of business operations – and help you make better decisions. You can choose how to use all of these to get the most value from our software – or speak with our SQLWorks team, to introduce something entirely new.

Closer Investigation

SQLWorks MRP answers the eternal question of every Purchasing Manager – ‘why do I need this?’ With our investigation button, the system can serve up an exact answer for where the source of demand for a stock item is coming from, what’s been found in stock, and allow the user to easily drill down to review the underlying Sales Order or Works Order.

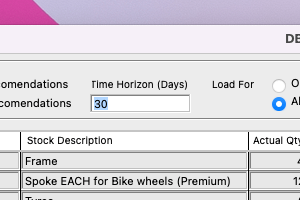

Flexible time horizons

Businesses can choose to shorten or extend the timescale for how far ahead SQLWorks ‘looks’ when doing your MRP run. Extending the timescale can give your earlier warning of future peaks in demand, helping you prepare earlier – while shortening the timescale helps bolster your cash flow by ensuring you’re only buying what you need imminently.

Demand Filtering

By default each MRP run looks at all demand for stock – across both new sales orders and outstanding works orders – but you can optionally switch this to ‘Customer Orders Only’ – prioritising customer needs in your calculations over any new in-house demand for reserves.

Warehouse Filtering

Your MRP run can be isolated to a single SQLWorks Warehouse for greater accuracy. This is especially important for companies with multiple warehouses either in the UK or overseas, because it helps avoid costly recommendations to move stock between warehouses where the distances are impractical.

MRP reporting

Your MRP run can also be run as a report – and there’s no obligation to create the Purchase or Works Orders MRP recommends. Even if you’re not quite ready to implement MRP yet, you can still use it as a guide to inform your own purchasing decisions, or to test the feature.

Non-Manufacturing

Wholesale, resale and other kinds of companies can still get value from MRP even they’re not doing any manufacturing – because buying and selling remains essential even if stock doesn’t go through any processing.

Thanks for reading! For MRP and manufacturing software expertise, please contact our team today.