We’ve introduced some important quality assurance tools into SQLWorks – allowing users to formalise their quality tests at different points of the stock control lifecycle.

Quality tests can be customised extensively and introduced at various stages of your workflow – including when receiving goods in, when manufacturing finished goods, or whenever you choose to test a batch that is being held in stock. We’ve also included new abilities to generate, store and integrate Quality Certificates – which will be covered more fully in a future blog post.

About Quality Testing

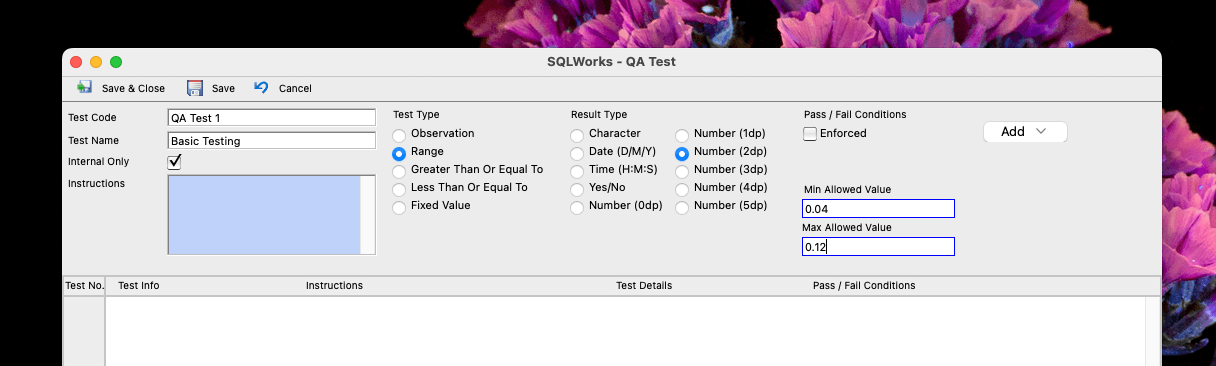

Quality tests may be created as standalone templates for your business, and can be customised for a wide range of different metrics. Saved tests can be either advisory or pass/fail, and include numerical measurements, dates, text answers and more – as well as specifying a level of precision for measurement, up to five decimal places.

You can assign tests (or a subset) as the default to any stock item in the stock ledger, formalising the ‘official’ set of tests that apply to that item.

Quality Testing on Receipt

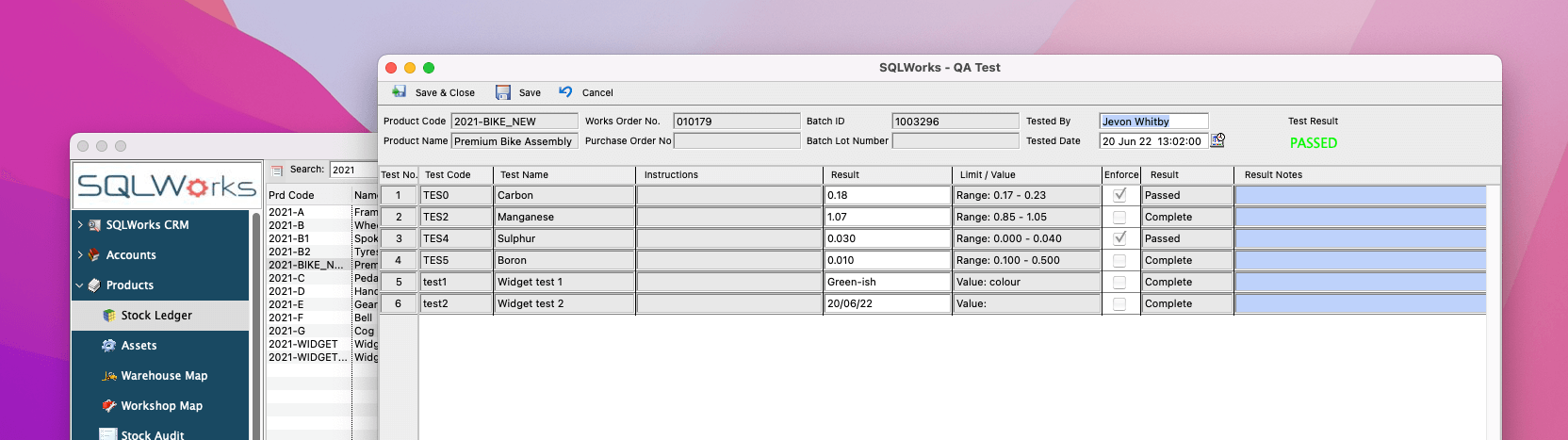

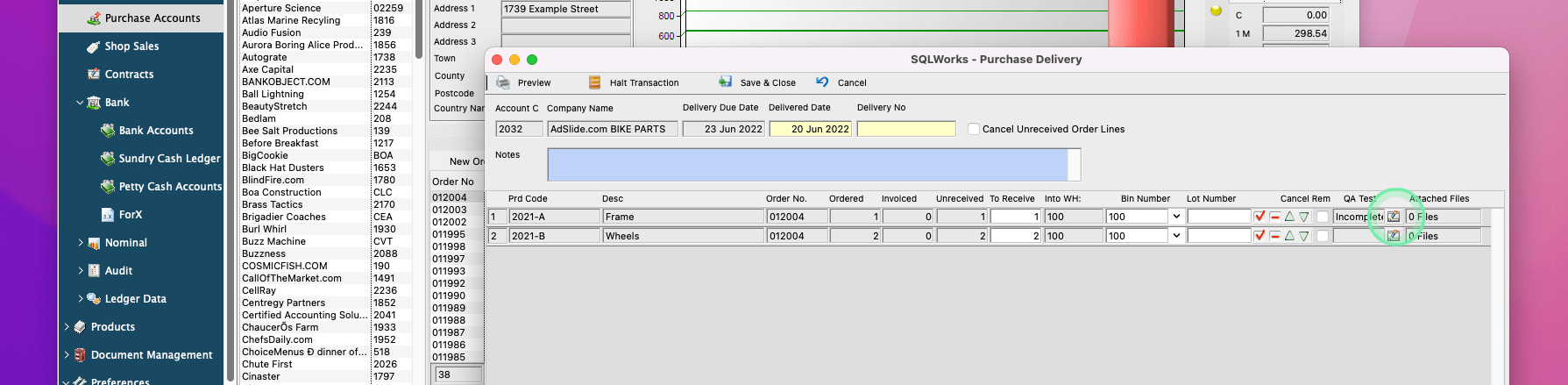

One of the most useful places to perform quality testing is at goods-in, at the point you receive inbound stock from a supplier. This can help check that you received what you purchase ordered, and that nothing is defective, damaged or missing.

To support this we’ve extended quality testing to the line-level of our purchase order receipt window – where the user can specify not only what goods were received, any variation to quantity, and those goods’ supplier lot number – but also save quality tests applicable to that line.

The correct tests for each line are automatically derived from that stock item’s defaults saved in the stock ledger, and results are automatically saved onto each new batch of stock that is created in the system when you receive the goods in – confirming that new stock has had its quality verified.

Quality Testing Manufacturing

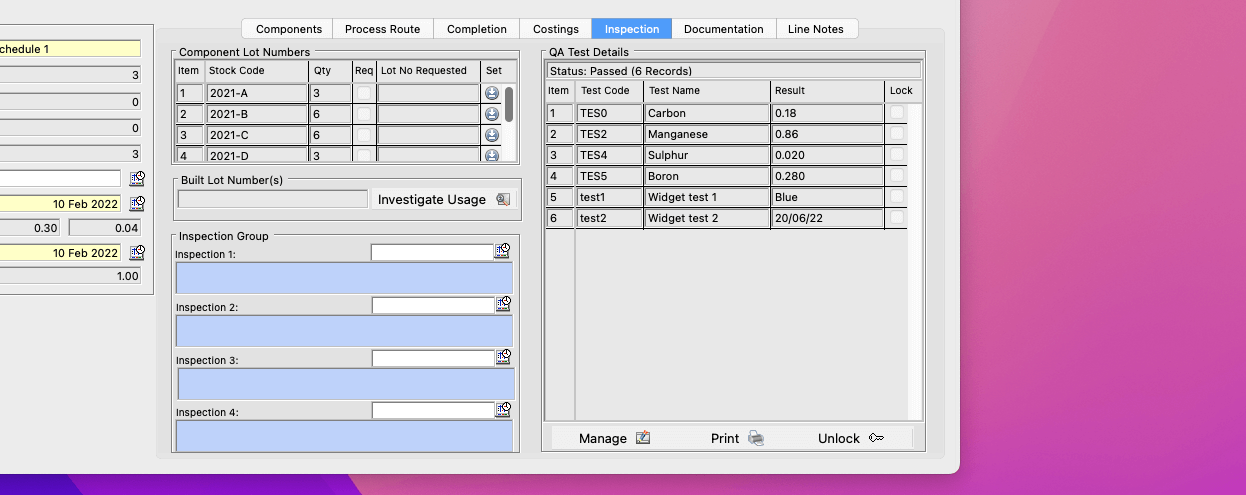

Quality testing is also now available within Works Orders, helping you to verify that your finished goods have been manufactured correctly for sale.

Testing is listed under the ‘Inspection’ tab of a Works Order, and can be completed for each batch of finished goods that will be created by the works order.

Once again, the default tests are drawn directly from those specified on that stock item’s defaults.

Batch Quality Testing

Alternatively, a quality test may be completed for any given batch of stock via the ‘Batch Info’ tab of the stock ledger.

This is useful when you want to complete quality testing as a standalone process, test a batch at random, or look for something advised by a supplier (such as during a recall.)

SQLWorks gives businesses exceptional traceability over batches, the quality of your component stock, and the quality of your finished goods.