Backflushing is an alternative method of allocating components or materials to manufacturing, whereby stock is deducted only after production has been completed.

Backflushing makes it easier to work with quantities that would otherwise be highly impractical to ‘pick’ for use on Works Orders, and is a particularly useful technique when:

-

- Components are too small or numerous to be ‘counted out’ in a sensible timeframe. (e.g.: screws, nuts, bolts, other low-cost parts used in volume.)

-

- When materials are divisible, liquid, molten, gaseous, in lengths, weights, or otherwise issued ‘approximately.’ (e.g.: paint, ingredients, chemicals etc.)

-

- Where a ‘spare’ quantity needs to be returned to stock after manufacturing is finished. (e.g.: scrapings, leftovers, recycled material.)

In SQLWorks every component on a Bill of Material (BOM) has a default allocation method – either ‘Standard’, ‘Backflush’ or ‘Return’ which defines how stock of this item will be ‘used up’ in the Stock Ledger. These work as follows:

-

- ‘Standard’ – This is the default, and is used for all items that need to be counted out in advance of production. Components will be removed from stock when the user clicks ‘Take’ on the Works Order, before production begins.

-

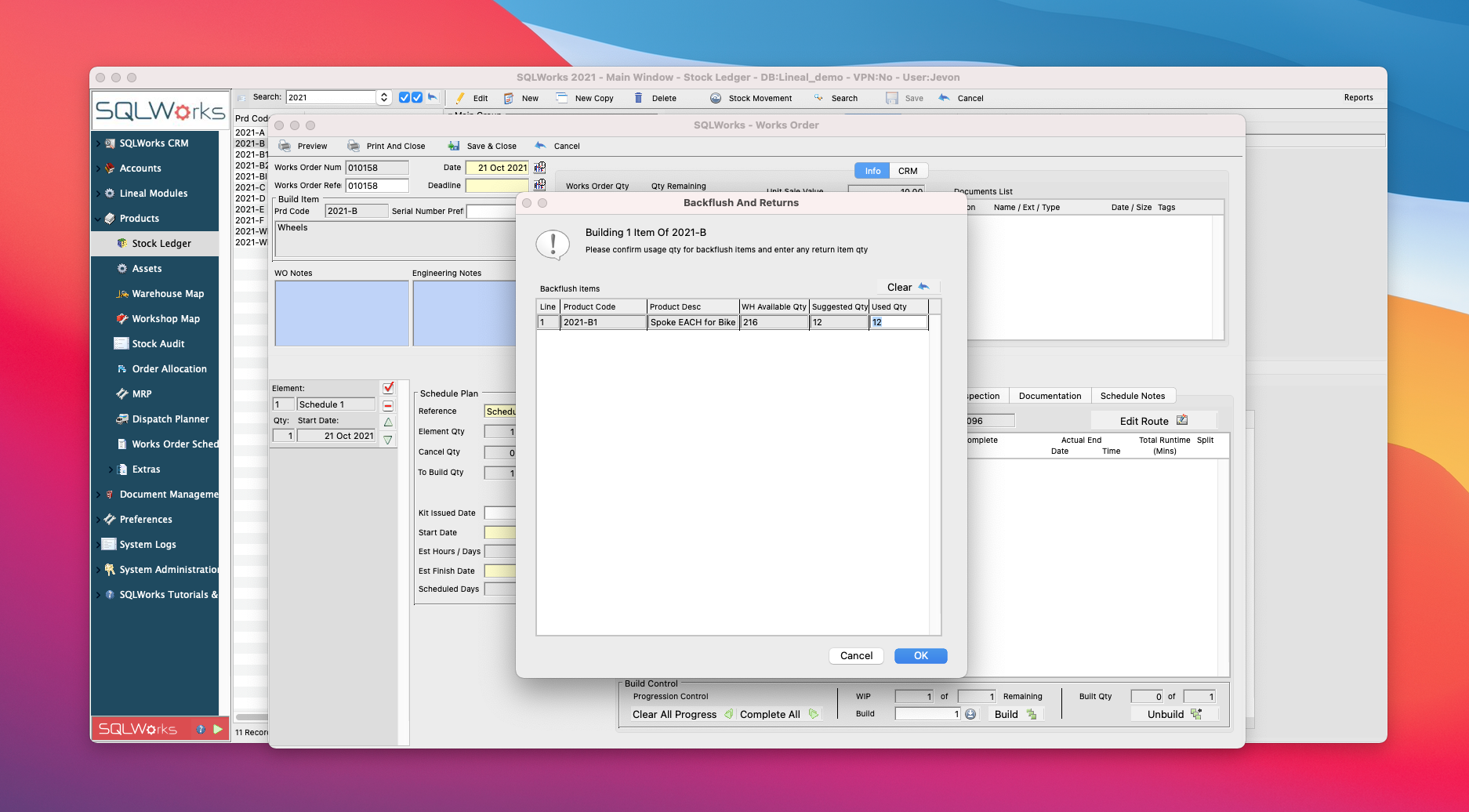

- ‘Backflush’ – Components will only be removed from stock after the Works Order is built, and the user is then asked to specify how much has been used.

-

- ‘Return’ – Similar to backflushing, however components will only be removed from stock after the Works Order is built, and the user is then asked to specify a ‘spare’ quantity that gets returned to stock.

By changing a component stock item to ‘Backflush’ on a BOM, nothing will be removed from stock at the ‘Take’ stage, instead being deducted only after that BOM has been ‘built’ on a Works Order. The user can then specify how much has (or hasn’t) been used.

This is significantly more practical for certain items – although production managers may need to initially estimate the stock quantity of a Backflush item that they expect to use on its BOM (e.g.: how much paint an item typically needs.)

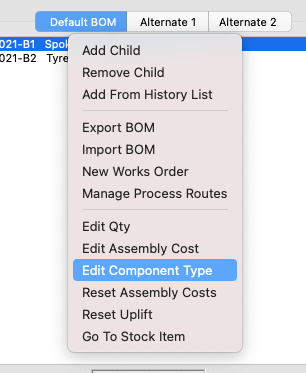

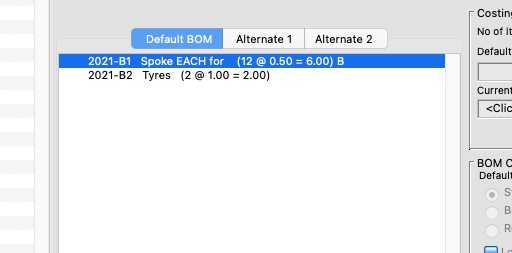

The user can edit a component’s default type by right clicking on it in a BOM, and choosing ‘Change Component Type.’ Components set to Backflush will be marked with a small ‘B’ symbol in the BOM.

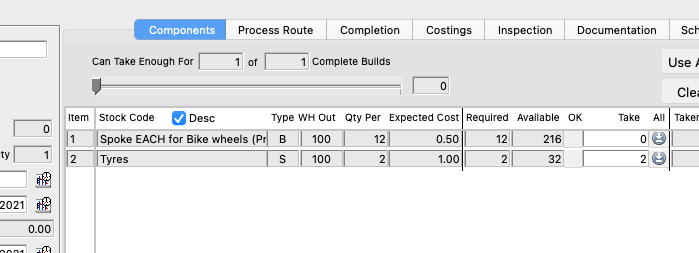

When ‘Taken’ within a Works Order, only Standard items will listed as being removed from stock, and Backflush items will always show a taken quantity of zero (with the user then prompted after the ‘build’ stage for the correct quantity used for Backflush, or quantity excess for Return.)

For many manufacturers, drawing down stock ‘post-production’ in this way may be the only way to accurately update your usage of resources. Using backflushing is an efficient way of tracking manufacturing using more fluid components, and allows SQLWorks to keep your production precise.