-

Multi-level Bill of Materials (BOMs)

-

Costed Assembly, including labour

-

Backflushing

-

Part cost blow-through from purchasing

-

Automated Engineer Documentation

Beginning life as a manufacturing platform, SQLWorks allows businesses to save a limitless number of component parts for product kitting.

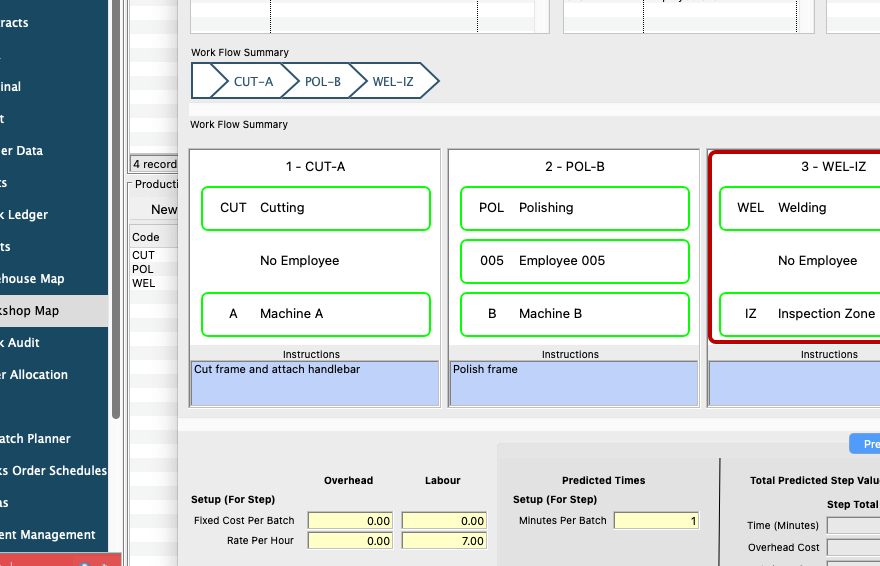

Save known ‘builds’ from individual parts, materials, labour and other resources with automated costing. Alternate kits, multiple build schedules, build locations and kits within kits allow you to configure your manufacturing process to be as simple or complex as you need.

Assign your bill of materials from the stock ledger, checking how many items can be made, generating works orders and accounting for the whole process within SQLWorks for more professional enterprise resource planning (ERP.)

Every part of the process is fully integrated with the SQLWorks CRM and Accounts modules with data updated in real time, ensuring that your whole business always runs in synchronisation with your works orders.

Related Help Guides:

“…We are clear that the faster adoption of technology will result in greater investment and in more manufacturing taking place in the UK.”

UK Gov ‘Made Smarter’ Manufacturing Review

Have a Question?

We love getting into the detail! Please contact our software team today – we’ll be happy to help.